Project location: Yantai, Shandong

Roof area: 180,000㎡

Roof system: Hoogovens® H65 Standing Seam Roof System

Yantai Changyu International Wine Production Center has a construction area of 270,000 square meters. The exterior of the building is in the shape of a horizontal oak barrel. It can produce 400,000 tons of wine and brandy per year. It is a wine and brandy wine production plant. Its building volume is large and the shape of the wine barrel is complex. It took nearly five years to complete. It is equipped with advanced technologies such as AGV unmanned laser-guided car, wine freezing automatic control system, super-speed filling production line, etc., and has achieved a high degree of automation and information management. It is a fully automated production workshop for wine in China.

Technical aspects

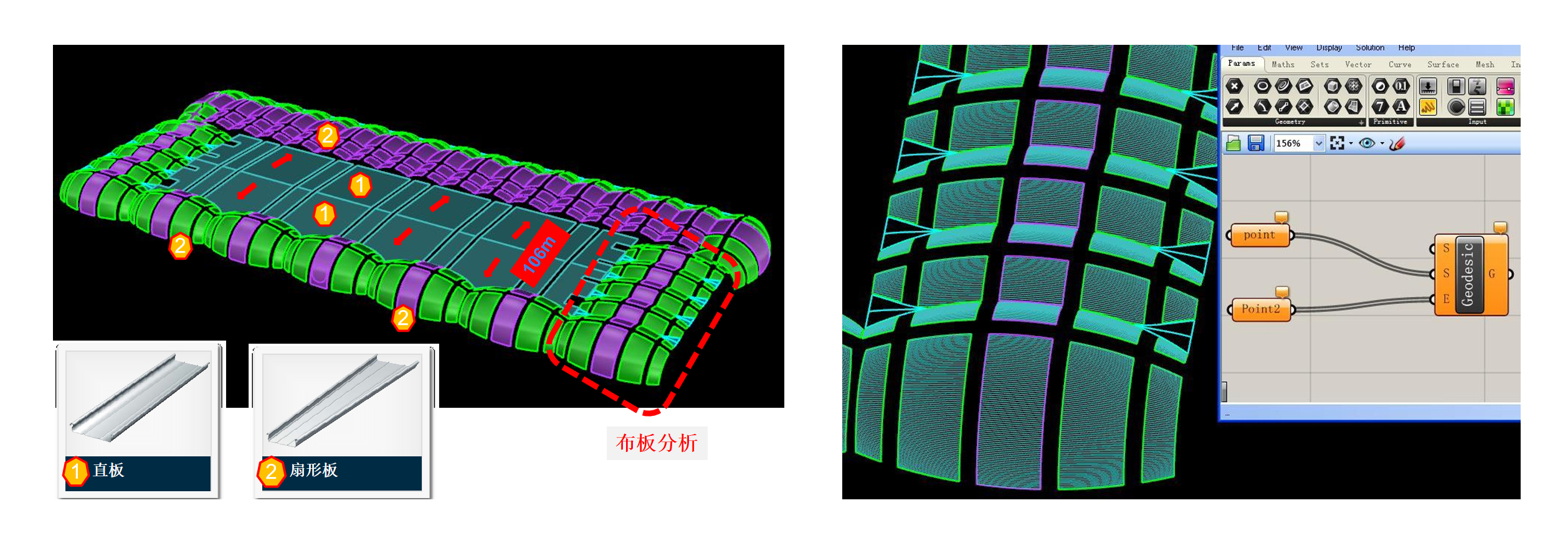

1. Typesetting analysis

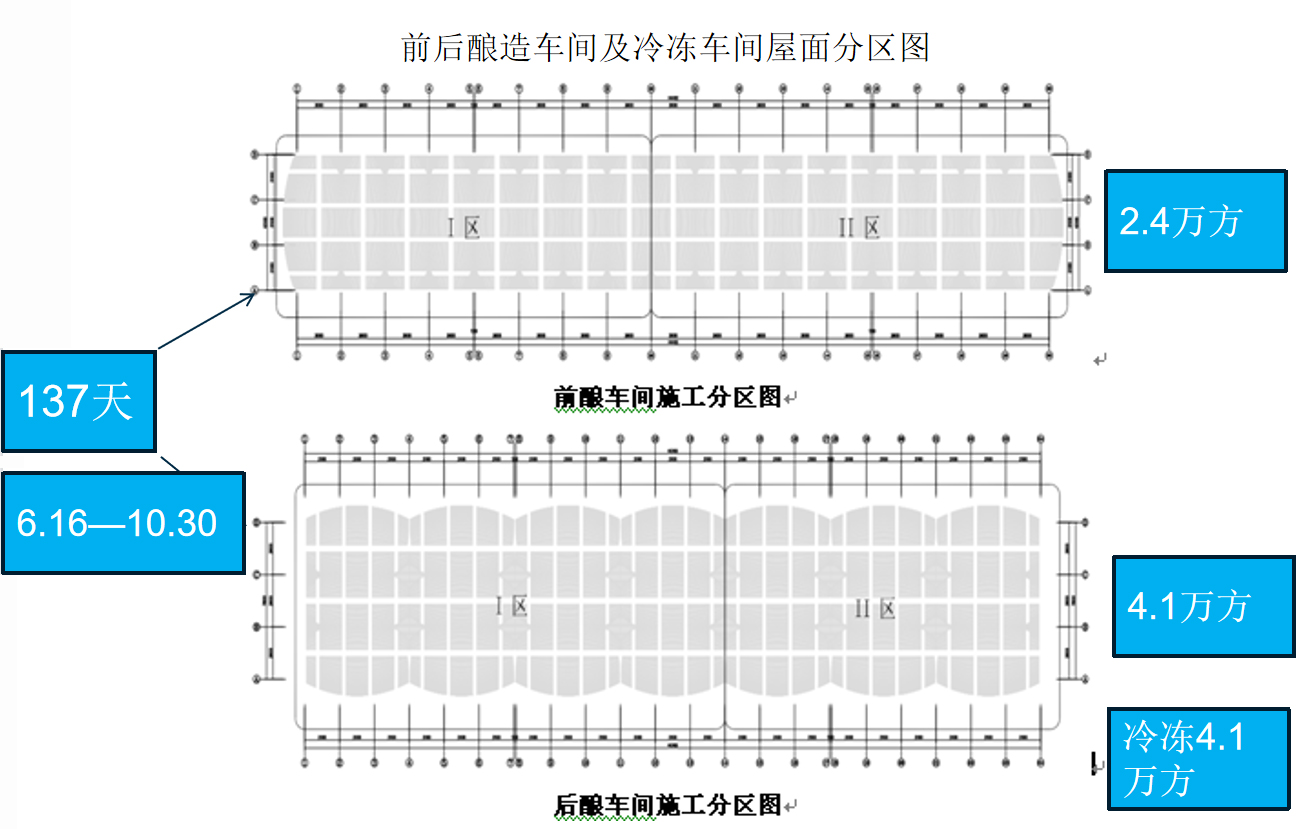

The project is divided into 4 production workshops, which are filling workshop, freezing workshop, post-brewing workshop and pre-brewing workshop. Each workshop has a large number of monomers, the shape of the barrel is extremely complex, and the technology is difficult, requiring the use of professional technical software for precise analysis.

Hoogovens' professional technical team uses Rhino software and Grasshopper software to analyze the layout of the three-dimensional model of each workshop, and accurately analyzes the layout and axonometric drawings of the straight and tapered panels of each workshop.

2. Technical solution

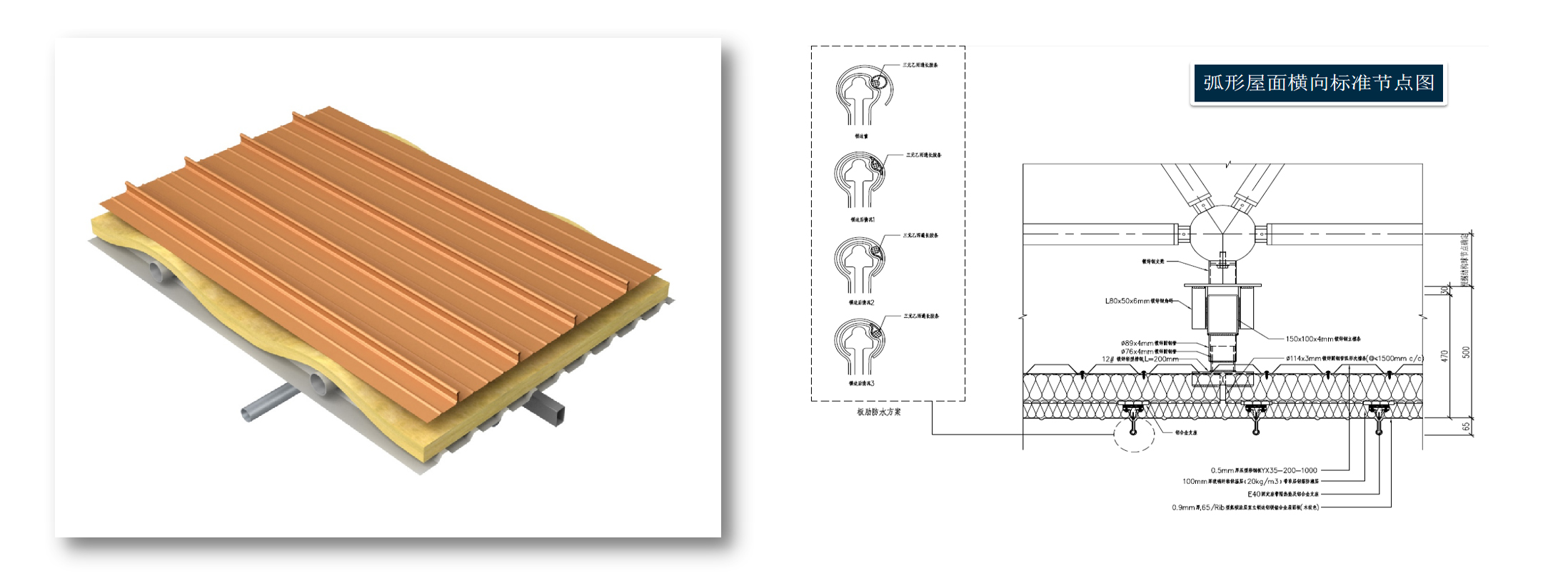

Through the calculation of thermal insulation performance, acoustic performance and anti-condensation performance, Hoogovens' professional technical team selected the standard system structure for this project and designed special curved roof and double-slope roof standard nodes.

At the same time, considering the hidden dangers of lighting and water leakage, we also designed the curved roof lighting skylight nodes and detailed node diagrams of roof ridges, cornices, gables, and inner gutters.

2. Construction solutions

1. Safety performance of metal roof structure system

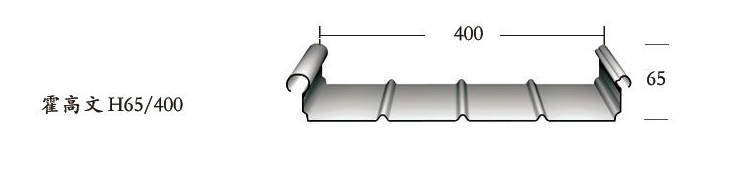

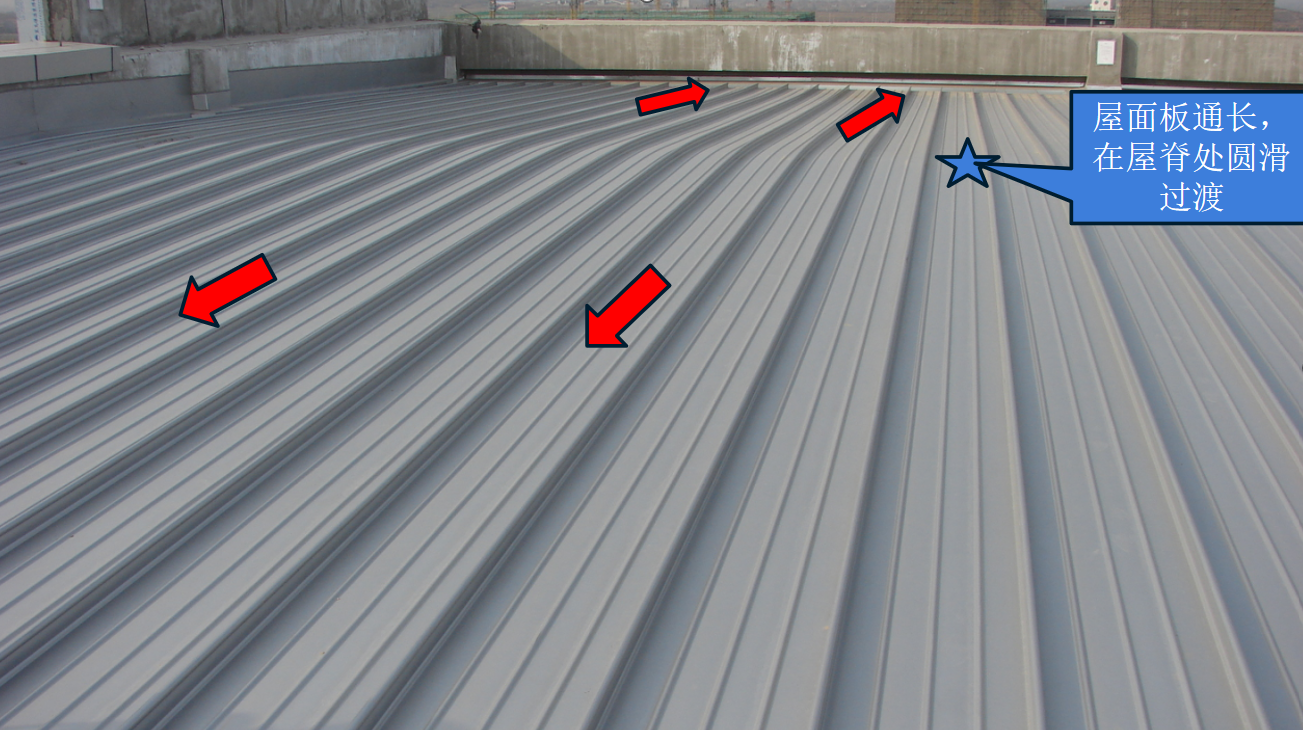

The spacing between the roof sub-purlins of this project is less than 1.5 meters, and the standing seam system adopts non-penetrating connections. According to the characteristics of the project's location, climate conditions and main structure, Hoogovens adopted the classic and mature H65/400 type roof waterproofing panel with high vertical edge concealed buckle type standing seam, which is different from the vertical edge seaming type low vertical edge roof waterproofing panel. As far as the panel is concerned, its strength is stronger, its wind pressure resistance is better, and its cost is relatively affordable.

2. Waterproofing of metal roofing system

Starting from several weak links that are prone to leakage on the metal roof, the following solutions are proposed for the waterproofing of the roof system to ensure that the project achieves the effect of no dripping or leakage.

(1) The selection of a mature and excellent roof system is the primary guarantee to prevent rainwater leakage from the roof

(2) Scientific and reasonable panel type and occlusal mode are the decisive factors to prevent rainwater leakage

(3) The concealed fixing method is an important condition to prevent rainwater leakage

(4) Rational design of joints and mature treatment process are the fundamental means to prevent rainwater seepage

3. Make a detailed construction schedule for each workshop to ensure that the project can be completed smoothly and on schedule.

Yantai Changyu Grape Wine Co., Ltd. is the first stock listed company in China's wine industry. Mr. Sun Yat-sen once wrote an inscription for it "Pin Zhongtiquan" ("Tiquan" is a sweet spring water, which is a praise for the quality of Changyu wine) It is the beauty of Changyu's emphasis on quality. Changyu Group not only pays attention to the quality of wine, but also is extremely strict in the selection of metal roof suppliers for Yantai Changyu International Wine Production Center.

Yantai Changyu International Wine Production Center’s wine barrels are complex in shape, small in size and large in number, and have extremely high requirements for roof insulation and waterproof performance. The basic functions such as lighting and ventilation are achieved through its beautiful and gorgeous shape, which organically combines Changyu's wine culture and architecture, fully demonstrates Changyu's corporate culture, and becomes a classic landmark building.